Tool Steel

Tool Steel

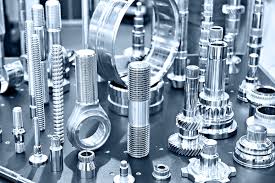

At Gururaj Global, we forge the foundation of innovation and precision with our high-grade tool steel. As leaders in the manufacturing sector, we commit ourselves to produce tool steel that sets the standard for excellence. Our advanced metallurgical processes ensure that each batch meets rigorous quality benchmarks, delivering unparalleled durability and performance.

Our tool steel is engineered for resilience, offering superior wear resistance and tenacity to meet the demanding needs of your tooling applications. Whether for cutting, molding, or shaping, our products promise consistent results even in the most challenging environments. Trust in Gururaj Global to equip your business with the steel that shapes the world.

Crafting Durability, Shaping Perfection

We provide all sort of Tool Steel

17-4 PH Stainless Steel Forgings

As a high-strength weldable alloy, 17-4 stainless steel provides the hardness and machinability needed for demanding applications, including mechanical components, biomedical tools, and structural components. Great Lakes Forge offers a full range of custom forging capabilities for 17-4 PH stainless steel. We can provide custom forgings up to 4,000 lbs., from 3.5″ to 18″ in diameter/thickness, and up to 120″ in length. With the industry’s fastest turnaround times, our forging services are ideal for high or low-volume production, as well as prototyping.

17-4 PH Stainless Steel Alloy: Properties & Characteristics

17-4 precipitation-hardening stainless steel features high strength, excellent corrosion resistance, and good mechanical properties, making it ideal for a wide range of applications. Characteristics of 17-4 PH stainless steel include:

- High strength

- High hardness

- High fatigue strength

- Good galling and stress corrosion resistance

- Exceptional oxidation resistance at temperatures up to 1,100°F (593°C)

- Excellent corrosion resistance (comparable to chromium-nickel grades)

Forged 17-4 PH Stainless Steel Shapes

To meet the needs of your unique project, we can create a wide range of forged shapes, including standard shapes like blocks, bars, rounds, and other custom geometries to meet your unique specifications. 17-4 stainless steel shapes we forge include:

- Flat bars

- Round bars

- Square bars

- Blocks

- Discs

- Flats

- Hubs

- Plates & Sheets

- Rectangles Rounds

- Sleeves Spindles

- Stepshafts

Other unique custom geometries

1.2714 Grade

1.2714 is a German Hot work alloy steel material grade.it is shock-resisting steel. it belongs to DIN 17350 standard. Digital Grade material number W-Nr 1.2714, Metal Steel grade 56NiCrMoV7. It is a die steel, use in extrusion molds, Hot Cast molds. like aluminum production, Aluminum cast mold. Our Tool Steel material 100 % ultrasonic tested at a good price. Small size steel products make by hot rolled, large size steel products make by forging.

DIN 1.2714 Grade Application:

1.2714 cold working tool steel is for general-purpose tools and dies where greater toughness is required, but with some sacrifice of abrasion resistance.

Typically used below applications

DIN 1.2714 Grade Application:

1.2714 cold working tool steel is for general-purpose tools and dies where greater toughness is required, but with some sacrifice of abrasion resistance.

Typically used below applications:

To meet the needs of your unique project, we can create a wide range of forged shapes, including standard shapes like blocks, bars, rounds, and other custom geometries to meet your unique specifications. 17-4 stainless steel shapes we forge include:

- Spindels

- Forming Rolls

- Punches

- Blanking & Forming Dies

- Trimmer Dies

- Clutch Parts

- Pawls

- Bearing

- Chuck Parts

- Rollers

- Knuckle Pins

- Shear Blades

Clutch Pins

H13 Tool Steel

H13 tool steel is an air hardening chromium die steel – H13 is used in a range of applications. The higher vanadium content improves resistance to heat checking and provides all round improvement to mechanical properties at elevated temperatures. Tools made with H13 can be water cooled without risk of cracking.

After normal heat treatment has been carried out it is suitable for nitriding 0.30mm (0.012″) deep.

Typical applications for H13 tool steel: hot forging and pressing dies, extrusion dies, mandrels and punches, hot chisels, pressure pads, extrusion stems and rams, blanking and bending tools, hot heading tools, backer blocks.